Imagine a world where your business runs smoothly, inventory issues become a thing of the past, and you have more time to focus on growing your enterprise. With automated inventory management systems, this isn't just a dream—it's a reality waiting for you to embrace.

You might be wondering how this technology can transform your daily operations and boost your efficiency. As you delve deeper into this article, you'll discover the incredible benefits and opportunities automated inventory management systems offer. This innovative approach is not just about saving time; it's about taking control of your business's future.

Are you ready to unlock the secret to streamlined success and take your business to the next level? Let's explore the world of automated inventory management systems together.

Automated Inventory Management Systems are transforming businesses. Automation brings many advantages. It streamlines processes, making operations smoother. Businesses gain efficiency and accuracy. Automation reduces manual tasks, saving time and effort. Let's explore the benefits of automation.

Manual data entry often leads to mistakes. Automation minimizes these errors. Systems automatically update inventory records. This ensures accurate data. Businesses can trust their inventory counts. Correct data prevents costly mistakes. Automation improves reliability.

Automation frees employees from repetitive tasks. Workers focus on strategic work. This boosts productivity. Automated systems track inventory levels efficiently. They alert staff to potential shortages. This proactive approach enhances workflow. Employees work smarter, not harder.

Automated systems reduce operational costs. Less manual work means lower labor expenses. Inventory accuracy prevents overstocking or understocking. Businesses avoid unnecessary purchases. Automation optimizes storage space. This leads to more savings. Investing in automation yields long-term benefits.

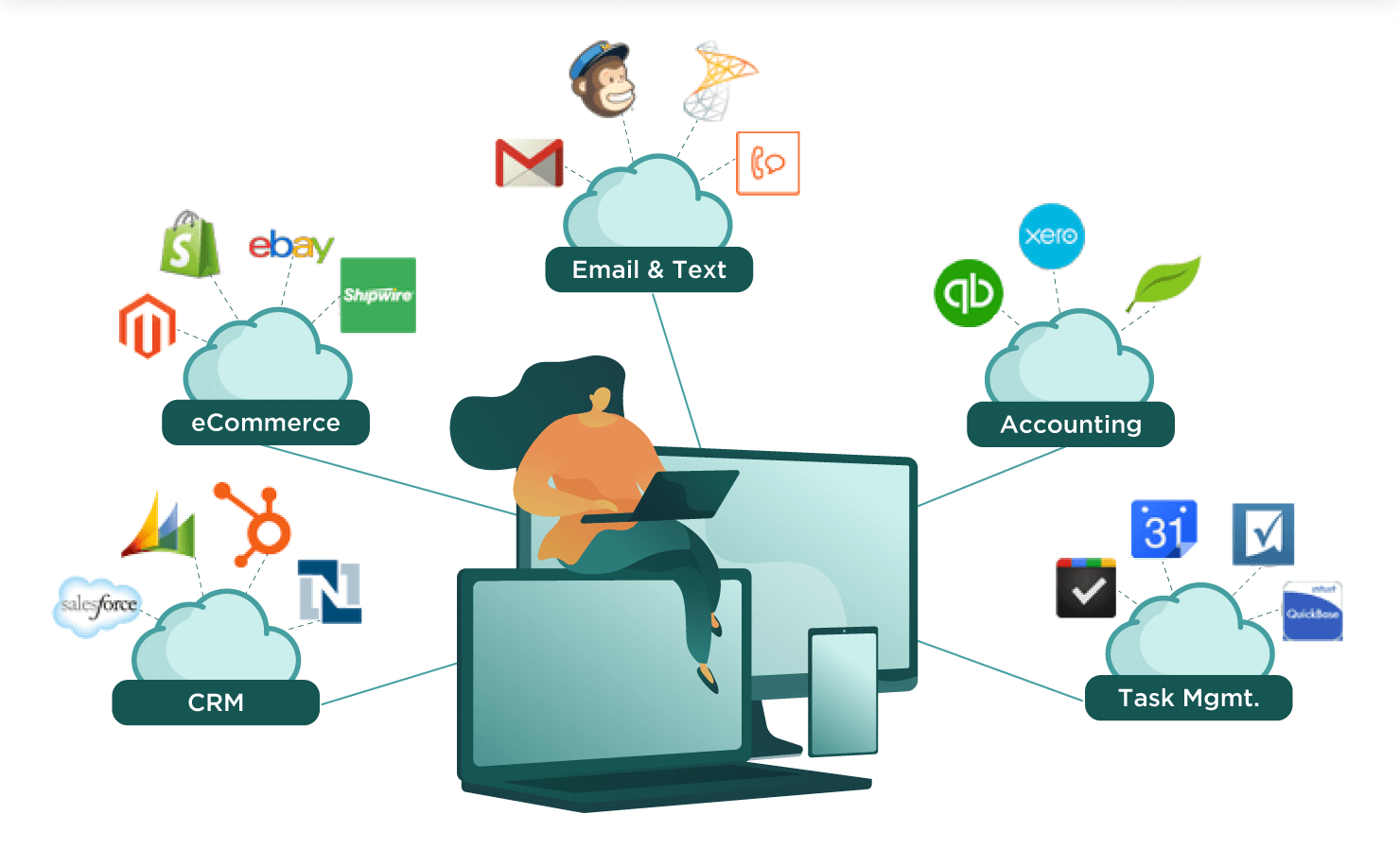

Automated inventory management systems bring efficiency to businesses. Understanding their key features helps in choosing the right system. These systems streamline processes, reduce errors, and save time. They offer real-time data, predictive insights, and seamless integration. Let's explore some crucial features.

Real-time tracking updates inventory instantly. It reduces stock discrepancies and ensures accuracy. Managers can check stock levels anytime, anywhere. Alerts for low stock prevent out-of-stock situations. This feature boosts productivity and customer satisfaction.

Predictive analytics forecasts future inventory needs. It uses historical data to predict trends. Businesses avoid overstocking or understocking. This feature optimizes inventory and cuts costs. It helps plan promotions and prepare for demand changes.

Integration capabilities connect inventory systems with other software. They ensure smooth data flow between applications. Sales, finance, and supply chain systems work together. This feature simplifies operations and enhances efficiency. Businesses gain a unified view of their operations.

Implementing automated inventory management systems involves choosing user-friendly software that fits business needs. Training staff ensures smooth adaptation, reducing errors and saving time. Regular updates keep systems efficient and responsive to changing demands, enhancing overall operational productivity.

Implementing an automated inventory management system can be a transformative move for any business, streamlining operations and increasing efficiency. But how do you ensure a smooth transition? The right implementation strategy is key. It involves assessing what you already have, choosing software that fits like a glove, and ensuring your team is ready to use it effectively. Let’s dig into each of these steps to help you make informed decisions.

Before diving into new software, take a close look at your current system. Identify what works well and what doesn't. Are there manual processes that slow you down? Pinpointing these areas helps you understand your needs better. This groundwork sets the stage for a smoother transition. Think about how your existing data can integrate with new technology. Compatibility is crucial. The more you understand your current operations, the better positioned you are to choose the right solution.

Selecting the right software isn't just about features. It's about finding a solution that aligns with your specific business needs. Consider scalability. Can it grow with you? Look for user-friendly interfaces that won’t overwhelm your team. What about budget? Balance cost with functionality. A more expensive option isn’t always better. Do your research, read reviews, and ask for demos. Make sure it supports your goals.

Even the best software is ineffective without proper training. Plan comprehensive training sessions for your team. This ensures everyone knows how to use the system efficiently. Don't underestimate the value of ongoing support. Encourage a culture of learning. Foster an environment where questions are welcomed and continuous improvement is encouraged. Does your provider offer reliable support? Check their service track record. Implementing an automated inventory system is a journey. What strategies will you use to ensure success? By planning carefully and engaging your team, you lay the groundwork for a successful transition.

Automated inventory management systems often face challenges like data inaccuracies and integration issues. Streamlining operations with real-time tracking and software updates offers practical solutions. Enhancing accuracy and efficiency ensures smoother processes.

Automated inventory management systems have transformed how businesses manage stock, but they come with their own set of challenges. Understanding these hurdles and finding effective solutions is crucial for any business looking to optimize its operations. You can tackle these challenges head-on and ensure your inventory management system works seamlessly.

Protecting sensitive data is a top priority. Inventory systems hold valuable information that must be safeguarded against breaches. Implementing strong security measures like encryption and regular software updates can make a difference. You might wonder, is your system secure enough? Regular audits can help you identify vulnerabilities before they become a threat.

As your business grows, so does the complexity of your inventory management. Automated systems need to scale effectively. But how do you ensure your system grows with you? Look for solutions that offer flexible scalability options. Systems that can adapt to increased demand without compromising efficiency are key. Does your current system allow for easy expansion? Investing in scalable solutions can prevent future headaches.

Change is often met with hesitation. Implementing new systems can face pushback from staff accustomed to old methods. To overcome this, highlight the benefits of automation, such as time savings and accuracy. Share success stories from other businesses that have made the transition. Are your team members aware of the advantages? Training sessions can ease the transition by making employees comfortable with new processes. You have the power to address these challenges with strategic solutions. By prioritizing data security, scalability, and embracing change, your automated inventory management system can thrive. What steps will you take to ensure your system's success?

Automated Inventory Management Systems are transforming businesses. They boost efficiency and reduce errors. Case studies show how different industries benefit. These real-world examples illustrate the positive impact. Let's explore two sectors: retail and manufacturing.

Retailers face challenges with stock management. Automated systems simplify these tasks. One large retailer improved stock accuracy by 25%. They reduced out-of-stock situations. Customer satisfaction increased significantly. Sales rose as a result. Inventory costs decreased, saving money.

A smaller retailer adopted automation too. They used real-time tracking for stock levels. This helped in quick restocking. Customer loyalty grew due to better product availability. The system provided data insights. This helped in predicting trends and optimizing stock.

Manufacturers need precise inventory control. Automated systems offer this precision. A medium-sized manufacturer reported fewer production delays. They implemented a system for tracking raw materials. Efficiency improved by 30%. Waste reduced, saving costs.

A large manufacturer faced complex inventory challenges. Automation streamlined their operations. They integrated with suppliers for real-time updates. Production schedules became more reliable. They saw a 20% increase in output. Quality consistency improved as well.

The future of automated inventory management systems is promising. Businesses are adopting new technologies to streamline operations. This helps them stay competitive in the fast-changing market. Let's explore some key trends shaping the future of inventory management.

AI is transforming inventory management. It predicts demand and optimizes stock levels. Machine learning analyzes data patterns. It helps businesses make informed decisions. AI tools provide real-time insights. This reduces the risk of stockouts and overstock.

IoT connects physical devices to the internet. It offers real-time tracking of inventory. Sensors in warehouses monitor stock levels. This enhances accuracy and efficiency. IoT reduces human errors. It improves inventory visibility.

Blockchain ensures transparency in inventory management. It records transactions securely. This builds trust among stakeholders. Blockchain tracks goods from suppliers to customers. It minimizes fraud risks. Businesses can access reliable data anytime.

An automated inventory management system tracks and manages stock levels using software and technology. It reduces manual errors, optimizes stock levels, and enhances efficiency. Businesses can track sales, orders, and deliveries in real-time, ensuring better decision-making and improved customer satisfaction.

This system saves time and resources effectively.

The four types of inventory management systems are Just-In-Time (JIT), Material Requirements Planning (MRP), Economic Order Quantity (EOQ), and ABC Analysis. JIT minimizes stock levels, MRP focuses on production planning, EOQ optimizes order quantity, and ABC Analysis categorizes inventory based on importance.

Automate inventory management in Excel by using formulas, conditional formatting, and macros. Implement tables for organized data. Use pivot tables for detailed reports. Regularly update your records and track stock levels efficiently. Consider Excel add-ins for enhanced functionality.

The three inventory control systems are Perpetual Inventory System, Periodic Inventory System, and Just-in-Time Inventory System. Perpetual tracks real-time inventory levels. Periodic checks inventory at intervals. Just-in-Time aims to reduce inventory by receiving goods only when needed.

Automated inventory systems simplify stock tracking. They reduce human error. Businesses save time and money. Efficient systems improve customer satisfaction. Real-time data aids in better decision-making. Companies can focus on growth. Inventory challenges become manageable. Technology offers seamless solutions. Embrace change for smoother operations.

Stay ahead with smart tools. Automated systems are easy to use. Small and large businesses benefit alike. Adapt and thrive in today's market. Simplify processes for success. Inventory management can be simple. Choose automation for a brighter future.